Torque Vectoring Technology

Torque Vectoring TechnologyTorque vectoring is the next step in AWD, its contribution being that it can get power to any wheel nearly instantly without having to use the brakes or cut power. Most current AWD control wheelspin by braking a spinning wheel or cutting the power from the engine. Torque vectoring is achieved by using redesigned differentials that can distribute power to the wheel or wheels that have traction. That means that wheels don't need to be stopped, and even better, you won't suffer from a sudden loss of power as you're negotiating an unexpected loss in traction. Some systems in use now or being developed work on FWD, RWD, and AWD cars, and can get power to any wheel or combination of wheels.

Passive |

Active |

|

|---|---|---|

Lateral Torque Distribution Control |

Lateral Torque Vectoring Control |

Lateral Braking Control |

| Mechanical Differential | Active Differential | Active Braking |

Audi / Torsen |

Mitsubishi S-AWC, Acura SH-AWD, ZF Torque Vectoring |

Mitsubishi S-AWC, M-Benz Active Braking, Porsche TV |

|

|

|

| The lateral torque distribution control unequally distributes the engine torque to the left and right wheels. The resulting difference in driving torque between the left and right wheels generates the yaw moment. This control, therefore, cannot effectively generate the yaw moment during cruising or deceleration when the engine torque is not large enough. |

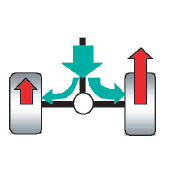

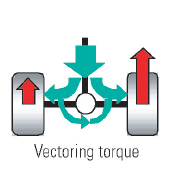

The lateral torque vectoring control transfers the torque from the left wheel to the right wheel, and vice versa, to generate an amount of braking torque on one wheel while generating the same amount of driving torque on the other wheel. The control of this type, therefore, can generate the yaw moment at any time regardless of the engine torque. Another advantage is that it does not affect the total driving and braking forces acting on the vehicle: no conflict with acceleration and deceleration operations. Although this control affects the steering reaction force when applied to the front wheels, it does not produce any adverse effects when applied to the rear wheels. Torque transfer is up to 100%. |

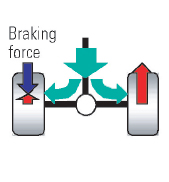

The lateral braking control applies different braking forces to the four wheels independently so as to produce a difference in braking force between the left and right wheels, which generates the yaw moment. As this control uses braking forces, it feels to the driver like deceleration, but the control is effective because it can generate yaw moment under a wide range of conditions of vehicle operation. Unlike passive EDL which applies the brakes to the wheel where it senses slippage, this is an active torque distribution where the torque is sent to the outside wheel to improve turn in. Torque transfer is limited to 50%. |

Torque Vectoring AWD Technology Manufacturers

|

|||||||||||||||||||||||||||||||||||||||||||||||||

Cars equipped with Torque Vectoring technology

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Benefits of Torque vectoring

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

Improved Tracking ExampleIce Walk Video |

Exceptional Handling ExampleSlalom test 6 x 100 ft (mph) SUVs

|

Mitsubishi Super All Wheel Control

|

|

S-AWC integrates management of its Active Center Differential (ACD), Active Yaw Control (AYC), Active Stability Control (ASC), and Sports ABS components, while adding braking force control to Mitsubishi Motors' own AYC system, allowing regulation of torque and braking force at each wheel. S-AWC employs yaw rate feedback control, a direct yaw moment control technology that affects left-right torque vectoring (this technology forms the core of S-AWC system) and controls cornering maneuvers as desired during acceleration, steady state driving, and deceleration. Mitsubishi claims the result is elevated drive power, cornering performance, and vehicle stability regardless of driving conditions. The S-AWC vehicle dynamics control system integrates management of all its AYC, ACD, ASC and Sport ABS components (see below) while adding braking force control to Mitsubishi Motors' own AYC system. As a result S-AWC elevates drive power, cornering performance as well as vehicle stability under all driving situations, from everyday motoring to emergency evasion maneuvers. ACD (Active Center Differential)The Active Center Differential incorporates an electronically-controlled hydraulic multi-plate clutch. The system optimizes clutch cover clamp load for different driving conditions, regulating the differential limiting action between free and locked states to optimize front/rear wheel torque split and thereby producing the best balance between traction and steering response. AYC (Active Yaw Control)AYC uses a torque transfer mechanism in the rear differential to control rear wheel torque differential for different driving conditions and so limit the yaw moment that acts on the vehicle body and enhance cornering performance. AYC also acts like a limited slip differential by suppressing rear wheel slip to improve traction. The first component of its type, AYC was first used in the Lancer Evolution IV launched in April 1996. It then took an evolutionary step forward in the Lancer Evolution VIII launched in January 2003 as the Super AYC when it switched from the use of a bevel gear to a planetary gear differential, thereby doubling the amount of torque it was able to transfer. In comparison to the system used in the Lancer Evolution IX, AYC now features yaw rate feedback control using a yaw rate sensor and also gains braking force control. Accurately determining the cornering dynamics on a real-time basis, the system operates to control vehicle behavior through corners and realize vehicle behavior that more closely mirrors driver intent. ASC (Active Stability Control)The ASC system stabilizes vehicle attitude while maintaining optimum traction by regulating engine power and the braking force at each wheel. Taking a step beyond the previous generation Lancer Evolution, the fitting of a brake pressure sensor at each wheel allows more precise and positive control of braking force. ASC improves traction under acceleration by preventing the driving wheels from spinning on slippery surfaces. It also elevates vehicle stability by suppressing skidding in an emergency evasive maneuver or the result of other sudden steering inputs. Sport ABS (Sport Anti-lock Braking System)ABS allows the driver to maintain steering control and keeps the vehicle stable by preventing the wheels from locking under heavy braking or when braking on slippery surfaces. The addition of yaw rate sensors and brake pressure sensors to the Sport ABS system has improved braking performance through corners compared to the Lancer Evolution IX. |

|

Honda Super Handling-All Wheel Drive

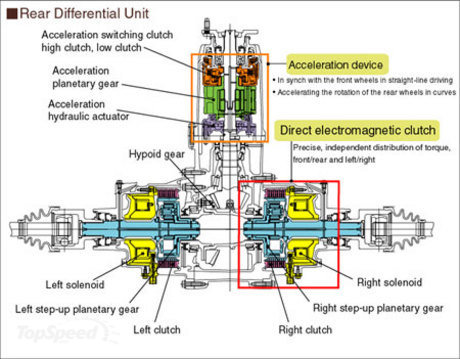

Honda’s SH-AWD system does not have any center differential or any limited-slip differential. The active type differential is mounted at the rear axle. The drive from propeller shaft first sent to an accelerator. The accelerator uses planetary gears to increase the rotation speed, creating a speed difference between the input and output. The speed difference can transfer driving torque to the rear axle utilizing electromagnetic clutches. Super Handling-All Wheel Drive or SH-AWD is a full-time, fully automatic all-wheel drive traction and handling system designed and engineered by Honda Motor Company. The system was first introduced in the North American market in the second generation 2005 model year Acura RL, and in Japan as the fourth generation Honda Legend. The company describes SH-AWD as a system that provides cornering performance that responds faithfully to driver input, and outstanding vehicle stability. The SH-AWD system combines front-rear torque distribution control with independently regulated torque distribution to the left and right rear wheels to freely distribute the optimum amount of torque to all four wheels in accordance with driving conditions. As first implemented in the Acura RL, SH-AWD allows torque to be continuously distributed between front and rear wheels from 70% front/30% rear to 30% front/70% rear, with up to 100% of the rear power being distributed to the outer left or right wheel to assist in cornering and dramatically reducing understeer. For example, in straight line full throttle acceleration, the RL is capable of distributing 40% of torque to the rear wheels and 60% to the front wheels. In a hard turn, of percentage of power distributed to the rear wheels, up to 100% of the rear wheel power can be distributed to the single, outer rear wheel. This action will push the rear around the corner, and helping with steering, reducing understeer and keeping the car balanced and controlled. The effect can be likened to steering in a row boat where applying more power to one oar can turn the boat. |

|

Torque Vectoring Systems by ZF

|

|

Audi / ZF Active Sport Differential |

BMW / ZF Vector Drive |

Torque-vectoring diffs have been around for a while, and the new system that has been introduced on the S4 will migrate to other performance models imminently, says Audi. If you want the clever rear diff on an S4 you’ll need to specify the $2000 Drive Select system plus an extra $1000 for the Sport Differential itself, supplied by German company ZF. The Audi system uses electronically-controlled and hydraulically-actuated clutches to adjust torque to each rear wheel, and works with Audi’s front/rear torque-splitting quattro system to maximise directional stability and minimise understeer. 'With the new sport differential influencing drive to the rear wheels, the S4 exhibits exceptional traction and stability,' says Audi. 'Close to the car’s handling limits, it acts like ESP, but with the principle reversed: corrective movements are not initiated solely by altering the engine settings or applying the brakes, but also by controlled redistribution of tractive force. As a result the car’s progress is distinctly smoother and more free-flowing, since ESP comes into action much less frequently.' For those of us without an engineering degree, Audi offers the following explanation of its system: 'Depending on steering angle, lateral acceleration, yaw angle, road speed and other signals, the car’s control unit calculates the most suitable distribution of torque to the wheels for How the Sports Diff integrates How the Sports Diff integrates every driving situation. When the steering wheel is turned, for example, or the car accelerated in a corner, power is redirected in a controlled manner to the outer rear wheel. This has the effect of 'forcing' the car into the corner so that the angle of the front wheels is followed accurately. The difference in tractive force between the left and right rear wheels also exerts a steering effect, so that the usual steering corrections by the driver are no longer needed. As a result understeer, or the tendency for the car to run wide at the front, is to all intents and purposes eliminated.' |

The rear differential at the heart of the BMW xDrive all-wheel drive system used in the X6, X6 M and X5 M goes beyond maintaining forward motion in adverse weather. This is a differential with brains - one smart enough to lend a helping hand in extreme cornering maneuvers. The version of xDrive in these BMWs includes a capability called Dynamic Performance Control whose purpose is to contribute what is called a yaw torque. To understand yaw torque, visualize a scale-model car with a toothpick stuck vertically through its roof. Spinning the tooth pick between your fingers mimics the vehicle’s yaw motion - movement about its vertical axis - experienced during cornering. In this example, your fingers supplied the torque that produced the yaw motion. All four tires generate the lateral forces that cause a vehicle to track around a corner in response to a driver’s commands at the steering wheel. Together, those four forces yield a yaw torque. But some tires work harder than others; in a front-heavy vehicle, the right-front tire does most of the work guiding the vehicle around a curve to the left. Dynamic Performance Control pitches in once the hardest-working tires have reached their traction limits. This added yaw torque - essentially an extra nudge to help the vehicle complete the cornering maneuver - is generated at the rear. By forcing the outside rear tire to push forward while the inside-rear tire pulls back a bit, a helpful turning force is generated about the imaginary vertical axis. What accomplishes this is the device, called Vector Drive by its German maker, ZF, is controlled by a computer that keeps abreast of the vehicle’s every move through speed sensors positioned at all four wheels. When cued by the computer, a planetary gearset inside the differential temporarily changes the speed ratio between the left and right wheels from the normal ratio of 1:1 in straight-ahead driving to 1.25:1, the outboard wheel strains to speed up while the inboard wheel strives to slow down. The resulting push-pull is the yaw torque that supplements cornering forces normally generated by the tires. It is like a bulldozer, which turns by changing the relative speeds of the tracks on each side. The beauty of this arrangement is that it works independently of the BMW’s propulsion system. Whether the driver is accelerating, braking or coasting through a tight turn, this computer-controlled differential is always on call to add a yaw-torque contribution. |

|

|

Mercedes-Benz Torque Vectoring Brake

The Torque Vectoring Brake in the 2009 S-Class Mercedes Extra provides additional safety and agility, by applying one-sided braking at the inside rear wheel when cornering. If ESP detects understeer, the new Torque Vectoring Brake generates a defined turning or yawing moment around the vehicle's vertical axis within fraction of a second. The resulting different torque distribution allows the S-Class to turn into the bend under precise control without loss of handling dynamics. The advantage of this solution over more complex mechanical solutions such as additional multi-disc clutches, an active rear axle steering, or an active differential: the Torque Vectoring Brake can be implemented with no extra weight.The disadvantage is that the torque transfer is limited to 50%. The S-Class steers more precisely when cornering thanks to targeted braking intervention at the inside rear wheel. According to Mercedes-Benz, the new 4MATIC all-wheel drive technology is integrated with a standard Electronic Stability Program (ESP), which maximizes the system's effectiveness in corners and in wet or slippery conditions, 4MATIC is always engaged and optimizing torque in every wheel. And to help ensure that power translates into control, 4MATIC incorporates our 4-wheel Electronic Traction System (4-ETS), an advance that monitors for the first sign of wheel slip and adjusts power delivery accordingly. By continually ensuring that power is evenly distributed among only those wheels with grip, 4MATIC can help keep the vehicle moving and under control even if only one wheel has traction. |

|

Porsche Torque Vectoring

2010 Porsche 911 TurboA new feature is an optional feature called Porsche Torque Vectoring. Priced at $1300, PTV uses the ability to apply the brakes individually to help the car turn into corners. Based on steering angle, vehicle speed, throttle position, and yaw rate, PTV gently applies the brake on the inside rear wheel to minimize understeer while entering corners. The system starts to phase out above 75 mph and is completely inactive by 100 mph.

|

![]()

| Belisso Ltd © 2009 |